Marca:

CBFI1、Product Application:

1). Aquatic products: raw shrimp, shrimp, fish meat, shells, etc.;

2). Meat: poultry meat, cut meat, etc.;

3). Noodles: dumplings, steamed stuffed buns, glutinous rice balls, spring rolls, etc.;

4). Conditioning food: marinated products, prepared dishes, etc.

2、Product Description:

The shape of the tunnel freezer is a rectangular tunnel, in which cold air circulates and food is quickly frozen when passing through the tunnel.The device has simple structure, fast freezing speed, can realize continuous production, and is suitable for assembly line processing. The food can be frozen within 60 minutes, and the center temperature can reach below -18°C. Incoming temperature or outgoingtemperature: +15°C/-18°C. The equipment is designed and manufactured in accordance with HACCP requirements to ensure food hygiene and safety.

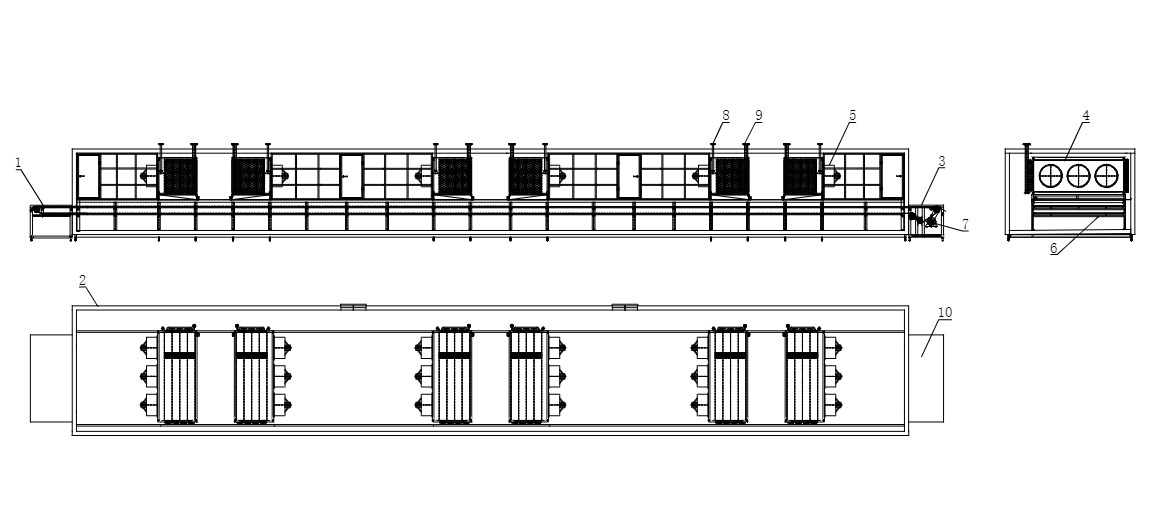

1. Feeding rack 2. Insulation storage body 3. Outlet 4. Evaporator

5. Circulating fan 6. Stainless steel footing frame 7. Transmission motor 8. Liquid supply pipe

9. Air return pipe 10. Mesh belt/plate belt

3、Product Categories

According to the different conveyor belts, it can be divided into mesh belt tunnel quick freezer and plate belt tunnel quick freezer.

Mesh Belt Tunnel Quick Freezer

The mesh belt tunnel quick freezer is suitable for quick-freezing processing of seafood, poultry meat, vegetables, fruits, pasta, dairy products and other foods. The freezing amount can be 100Kg/h--2000Kg/h.

Structural features:

a 、Simple structure, convenient operation and long service life.

b 、The conveying mesh belt is made of high-strength SUS304 stainless steel mesh, which is safer to use, and the frozen products will not leave traces directly on the surface of the mesh belt. Mesh belt width can be selected upon request.

c 、According to the production requirements, the combination of single and double mesh belts can be selected.

d 、The thermal insulation storage body is made of double-sided SUS304 stainless steel polyurethane storage board, with inspection doors, double-layer sealing devices and heating devices to prevent freezing.

e 、The air guide device in the warehouse adopts high-efficiency and low-noise axial flow fan and thermal fluctuation technology, and the freezing efficiencyis increased by about 15%-30%.

f 、Use water to wash the cream to ensure cleanliness. The evaporator is made of aluminum alloy material, aluminum tube and aluminum fins, which is easy to clean. The design of variable blade distance can effectively prevent frost blocking and prolong the timeof frost flushing. The unique liquid supply method makes the heat exchange more sufficient and the effect more obvious.

g、 The imported frequency converter realizes inorganic speed regulation, and the freezing time can be adjusted continuouslyaccording to the needs, which can adapt to various freezing processes.

h、 Stainless steel electric control box, stable quality, safe and reliable, easy to operate. The control system is equipped with a special alarmdevice andan emergency button to ensure the safe operation of the equipment.

Plate Belt Tunnel Quick Freezer

The plate-type tunnel quick-freezing machine is suitable for quick-freezing processing of high-moisture, soft, and liquid foods, such as fresh meat, fish fillets, shrimp, scallops, pasta and other foods. The freezing amount can be 100Kg/h-2000Kg/h.

Structural features:

a、 Simple structure, convenient operation and long service life.

b、The storage body is made of rigid polyurethane foam, which has good thermal insulation performance. All internal parts are made of SUS304. high-quality stainless steel, which is easy to clean and meets HACCP requirements.

c、Imported stainless steel strips are used, with high toughness and smooth surface.

d、The ice scraping device of the feeding belt can reduce the damage to the steel belt caused by ice and foreign objects.

e、According to the production requirements, single and double strip combinations can be selected.

f、Use water to flush the cream to ensure cleanliness

g、The imported frequency converter realizes inorganic speed regulation, and the freezing time can be adjusted continuously according to the needs, which can adapt to various freezing processing

4、Product Performance Characteristics

1). The "heat fluctuation" blowing method is adopted, and the freezing speed is fast;

2). Rapid freezing at -35°C;

3). It is made of 304 stainless steel spring wire, and the surface is flat; the imported frequency converter is used to realize stepless speed regulation;

4). The cooling fan adopts variable blade pitch, and the frosting interval is long to ensure the continuity of production;

5). The warehouse body is made of polyurethane foam, double-sided 304 stainless steel, good heat preservation effect, hygienic and easy to clean.

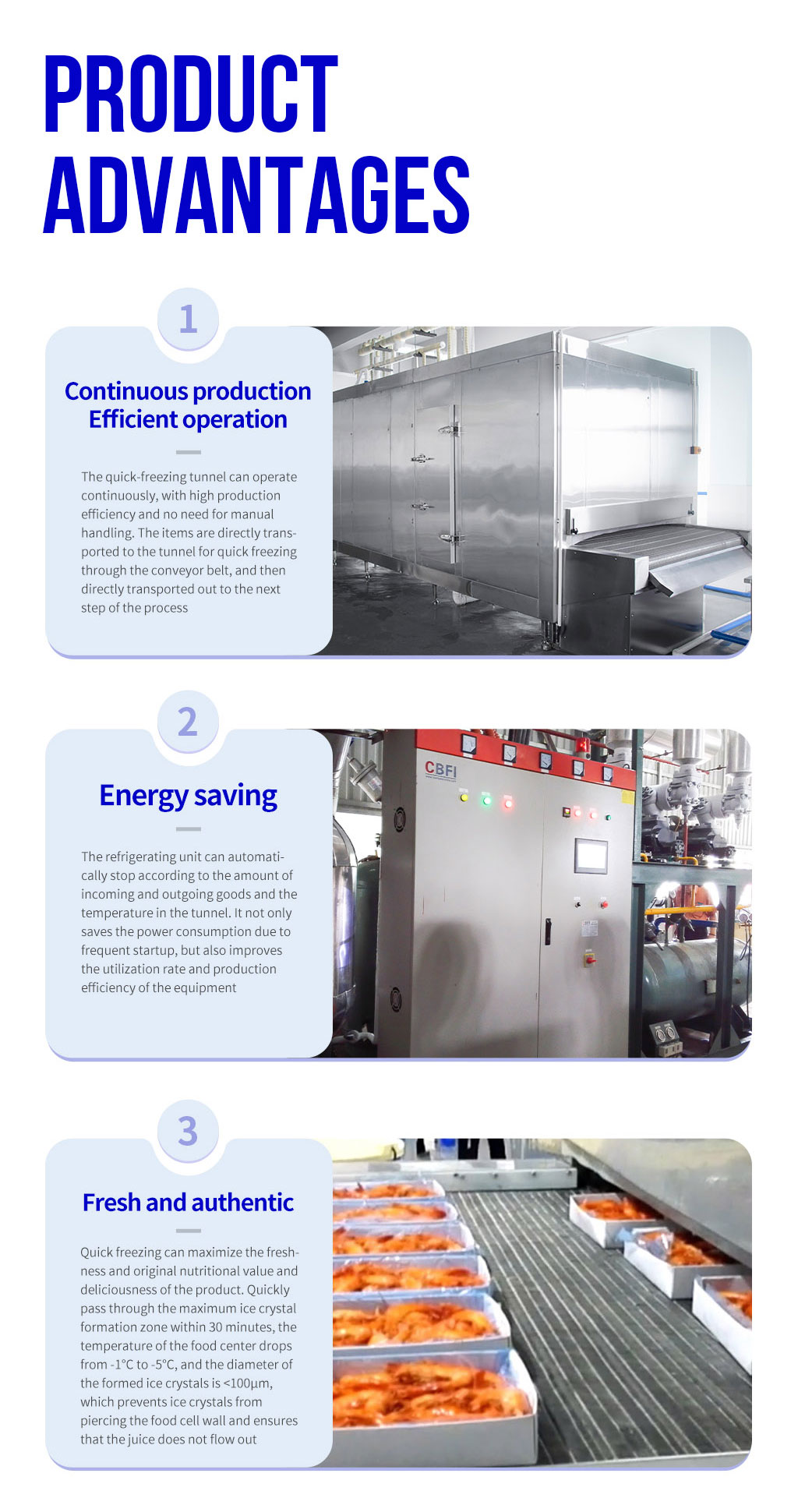

5、Product Advantages

1). Continuous and uninterrupted production, reducing manual operation The quick-freezing tunnel can realize continuous quick-freezing work and improve production efficiency. However, the goods entering and exiting the traditional quick-freezing warehouse can only be realized manually. Manually put the food into the quick freezer, start the refrigeration equipment, and quickly cool and freeze the food. When the food freezes, the refrigeration unit turns off. Manually move the goods out of low-temperature cold storage or other places. The use of quick-freezing tunnels can save manual handling procedures. The goods are transported to the tunnel by the conveyor belt. After the goods pass through the tunnel, they are quickly frozen and then shipped out for the next step.

2). Quickly freeze food to maintain the original nutritional value of the food to the greatest extent. The food with color and aroma will quickly pass through the maximum ice crystal formation zone within 30 minutes, so that the core temperature of the food will drop from -1°C to -5°C , The diameter of the formed ice crystals is less than 100μm, which prevents the ice crystals from falling off and piercing the cell wall, reduces the outflow of juice, and quickly freezes food. It is characterized by maintaining the original nutritional value and color, aroma and taste of food to the maximum extent.

6、Company Profile

Guangzhou IceSource Refrigeration Equipment Co., LTD is founded in January of 2004,which is established on the management and manufacture basic of Guangzhou Vista M&E Equipment Co., Limited.

Nuestra fábrica estaba ubicada en el distrito de Panyu de Guangzhou, provincia de Guangdong, está cerca de dos puertos famosos del sur de China, el puerto de Huangpu y el puerto de Nansha, y no lejos del aeropuerto de Baiyun. Es conveniente para la carga y el transporte de mercancías y para que los clientes vengan a visitar nuestra fábrica. Nuestra empresa se especializa en la investigación, diseño, producción y venta de máquinas de cubitos de hielo de gran producción, máquinas de bloques de hielo, máquinas de placas de hielo, máquinas de tubos de hielo y máquinas de hielo raspado, y sus equipos accesorios, por ejemplo, cámaras frigoríficas, grúas, máquinas trituradoras de hielo y pronto. El diseño de salida de la máquina puede comenzar desde una sola máquina de hielo pequeña para producir 1 tonelada de hielo por día hasta un sistema de fabricación de hielo completo a gran escala para producir 50 toneladas de hielo por día. Todos los componentes, desde la elección de la materia prima hasta el procesamiento y los productos terminados, pasan una estricta inspección, un estricto control de calidad, asegurar completamente el sistema de hielo con excelente calidad. Los productos se aplican ampliamente en diferentes campos, como la industria alimentaria, grandes cadenas de supermercados, minoristas, productos acuáticos, industria química, conservación de agua, plantas de energía, atención médica, grandes proyectos públicos, refrigeración de minas, industria química, etc. Investigación independiente y El diseño es la fuente de tecnología para actualizar, nuestra empresa posee dos tecnologías patentadas: intercambio de calor de placa plana y gas de calor circulante para caída de hielo. Estas dos patentes han mejorado en gran medida la estabilidad y la seguridad de nuestra máquina para hacer hielo y aseguran que la máquina ahorre energía de manera destacada, su tasa de ahorro de energía es superior al 30%. Comienza una nueva generación de productos de ahorro de energía. Los productos Icesource han pasado los certificados ISO9001, ISO14001 y CE. Hemos seguido el estado del servicio de seguimiento de nuestros productos, tiene récord de más de 400 clientes en más de 30 países de África, Medio Oriente, Sudeste Asiático, Australia y América del Sur. Nos brinda una rica experiencia y datos valiosos para mejorar nuestros productos para diferentes condiciones ambientales. Icesource toma "productos de alta calidad cuidadosamente creados y un servicio sincero" como principio de la empresa, sigue desarrollando y perfeccionando nuestro sistema de ventas y sistema de servicio posventa, combinado con ventajas propias, aprendizaje continuo experiencia de ventas maduras en el extranjero y atender las tendencias del mercado nacional e internacional y demandas. La empresa se adhiere al principio de igual énfasis en los beneficios sociales y económicos. Haremos todo lo posible para ofrecer al cliente un servicio y soporte oportunos e integrales. Icesource se adhiere a las ideas corporativas orientadas a las personas, la tecnología primero, ve las necesidades prácticas del cliente, mejorar la calidad de vida de las personas y el medio ambiente para el ser humano existente como un deber. Reuniendo tecnología fuerte, talento profesional e instalaciones avanzadas, mejoramos continuamente la tecnología de fabricación de hielo, para ser líderes en la industria de máquinas de hielo.